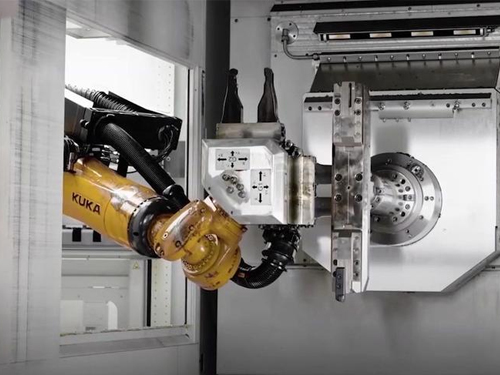

Precision parts processing of vacuum manipulator and atmospheric manipulator for wafer handling; Parts surface resistance to high temperature, corrosion and high cleanliness cleaning and vacuum packaging requirements, delivery of more than 500 sets

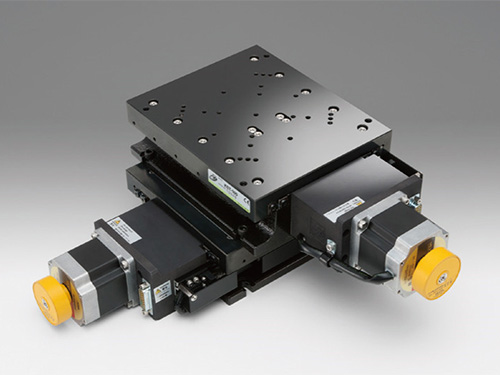

The company develops precision sliding table for optical testing equipment, genetic testing equipment and automation equipment. The positioning accuracy of the slide table can reach sub-microns, the shipment volume is more than 1000+, and the brand of "XYZ MT" is owned.

With 400㎡ million dust-free assembly workshop, to provide customers with one-stop parts processing, standard parts procurement, optical and electromechanical micro-assembly, mechanical accuracy, electrical signals, air pressure & Vacuum and other inspection services, assembled into modules with specific functions, greatly reducing customer installation time. Customers cover domestic and foreign semiconductor manufacturers, product performance and quality are recognized by customers.

The company R & D and production of CMM, metrological CMM, large gantry CMM, optical measuring system, gear measuring system, customers all over the world, to provide customers with complete measuring solutions.

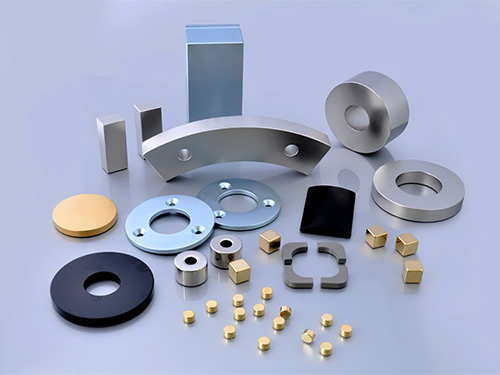

The company has cooperated with manufacturers for more than 10 years, and can realize a variety of high-clean, ultra-strong corrosion resistance technology and testing capabilities, including chemical cleaning, anodizing, electrolytic polishing, nickel plating, electroless nickel plating and ceramic spraying.

Learn more+

Parts appearance random polishing, sealing surface smooth polishing and precision cleaning technology; Design and produce special polishing equipment according to customer requirements to ensure the polishing effect.

The company established mechanical design, electrical design and software teams, tailor-made for customers of automatic processing line, automatic detection line, fixture, servo slide R & D and manufacturing capabilities